The difference between environmental friendly turf and unfriendly turf

- 03/17/2020

First of all, the artificial lawn system usually consists of six modules: grass fiber, rubber grain filling layer, quartz sand filling layer, base cloth, backing and foundation. Among them, the artificial lawn composed of grass fiber, base cloth and back glue comes from the manufacturer of artificial lawn; Rubber granules and quartz sand shall be purchased by the user or the project contractor; The foundation, built by the user or the contractor, is usually cement or sand and there are few environmental problems.

Fibre

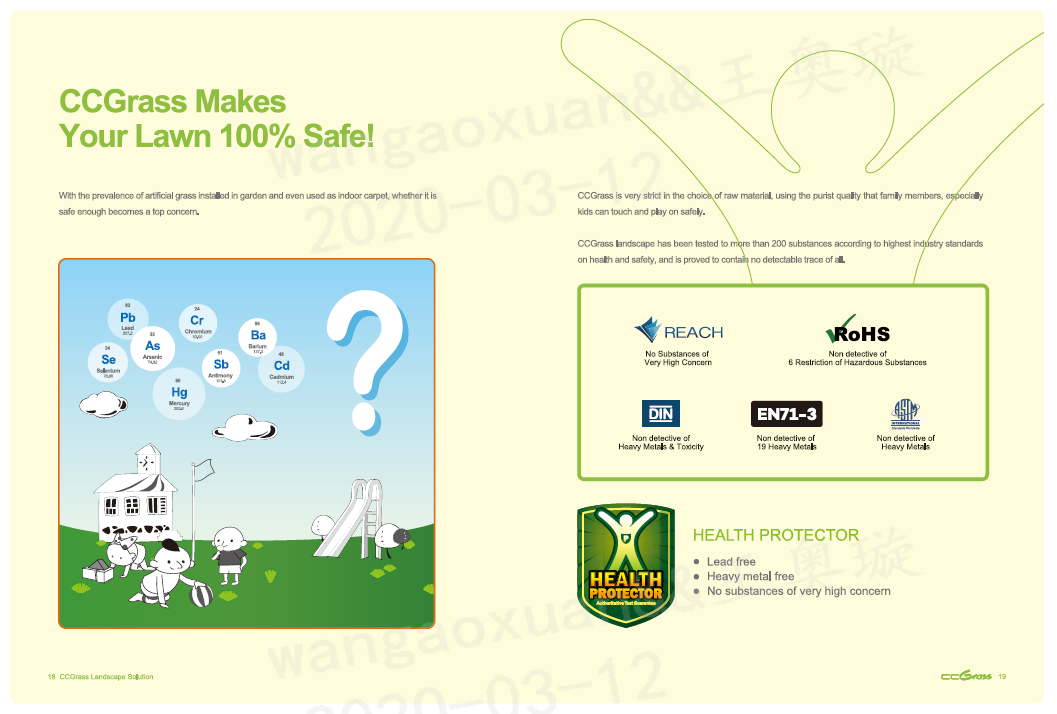

The main environmental protection requirements of grass fiber are heavy metals antimony, arsenic, barium, cadmium, chromium, lead, mercury and selenium. They must not exceed the quantity specified in the relevant standard. The green grass fiber is made of new high quality olefin polymer, with high temperature color master and agent free of heavy metals. Because the variety of raw materials is relatively small, the quality can be well controlled, they will not cause irritation to the skin, and will not cause harm to the environment. For example, the grass fiber used by some companies has passed SGS food-grade test and passed European heavy metal test without any heavy metals.

fibers and then left in the grass fibers, causing potential poisoning injury to long-term contacts and irreversible harm to the water body and soil environment.

Base cloth

At present, there are only a handful of large-scale artificial lawn bottom fabric manufacturers, all of which have relevant certificates of qualification and quality. Their environmental protection is reliable, basically will not appear environmental protection problem.

Back glue

At present, there are two kinds of glue for artificial lawn: styrene-butadiene latex and polyurethane. Polyurethane, as long as it is the use of specifications, will not affect the environmental protection of the material. Butadiene latex is made by butadiene and styrene polymerization. The environmental protection butadiene latex is qualified in quality and the reaction process is carried out in the reaction kettle under precise control, so that it meets the environmental protection standard. But this process and equipment is very expensive, not all manufacturers can achieve, only a few large manufacturers, can achieve this requirement, so the price of latex manufacturers are not the same, quality is uneven.

Rubber infill

The significance of rubber particle filling is to make the artificial lawn with natural lawn like elasticity, rolling performance and good interaction of human grass and ball grass. Rubber particle filling is an important part of the artificial turf system, and it is also the part of the system in direct contact with people. The environment-friendly rubber particle is made of styrene butadiene rubber, color masterbatch and auxiliary agent. The production process is strictly controlled to ensure the elasticity of the rubber particle. At the same time, it does not contain heavy metals and has no peculiar smell. However, the rubber particles made by this method are more expensive and are only used in a few sites. Most sites use rubber particles made from crushed rubber products such as tires, soles, wires and cables. So this kind of rubber itself composition is complex, in the processing or use process may form a reaction between different additives, produce toxic and harmful substances, causing harm to the user, the environment.

To learn more, please check at the knowledge center for artificial grass.