The Ultimate Guide to Artificial Grass Infill in Modern Turf Systems

- 04/30/2025

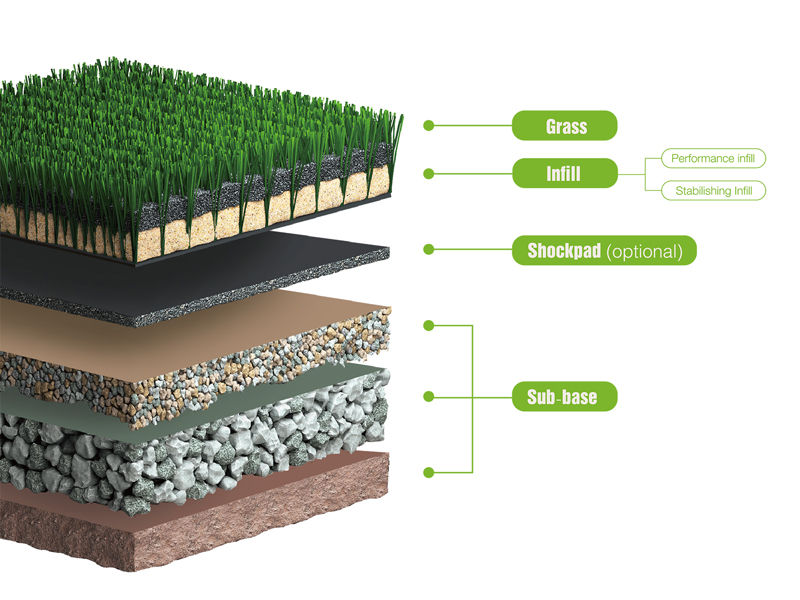

Artificial grass infill is a key component of synthetic sports fields. This material, placed between the blades of artificial turf, provides cushioning, stability, and a natural feel, ensuring the surface meets performance and safety standards.

In this guide, we’ll explore what artificial grass infill is, the different types available, and the alternative of non-infill turf, to help you make informed decisions for your project.

In this article:

What Is Infill for Artificial Grass

Infill is an integral part of many artificial turf systems, working alongside components like the synthetic grass carpet and optional shockpad to deliver a high-performing surface. Infill options vary widely, from sand and SBR to natural choices like cork or coconut materials.

Is infill necessary for artificial grass?

In most synthetic turf systems, yes, infill plays a critical role in ensuring the turf functions effectively. Its role is vital for several reasons:

Blade support: Infill provides structural stability to grass fibers, helping them stay upright. Typically made of polyethylene (PE), these fibers are durable but lack natural stiffness and tend to lie flat without support. To ensure resilience and long-term performance, turf systems rely on infill particles and/or pair the fibers with strong curled yarns.

Impact absorption: Infill serves as a critical safety component in sports surfaces by effectively dissipating kinetic energy during high-impact movements. When athletes experience sudden impacts from falls or jumps, the infill converts vertical impact forces into horizontal energy dispersion across the surface matrix.

Surface stability: By adding weight, infill prevents the turf from shifting or wrinkling, maintaining a smooth, reliable surface. The tightly packed particles create a cohesive base that anchors synthetic fibers, resisting lateral movement even during sharp directional changes.

Different Types of Artificial Grass Infill

In 3G artificial turf systems, infills are broadly divided into performance infills, which enhance safety and playability, and stabilizing infills, such as silica sand, which provide ballast and turf stability. Other turf types, like 2G or non-sports turf, may use only stabilizing infills or none at all.

The table below details common infill materials and their properties:

| Infill Material | Type | Material Composition | Key Features | Considerations |

| Silica Sand | Stabilizing | Mineral (silicon dioxide) | Affordable, widely available, great for ballast; often paired with performance infills | Offers minimal shock absorption, may compact over time |

| Coated Sand | Stabilizing | Polymer-coated silica sand | Improves stability, coating ensures long-term consistency | Higher cost than raw sand |

| SBR | Performance | Recycled rubber (ground tires) | Good shock absorption, improves traction, withstands intense use; cost-effective | Can retain heat; concerns over microplastics |

| EPDM | Performance | Synthetic virgin rubber | Reduces impact, performs well in high temperatures; maintains quality over time | More expensive, less common |

| TPE | Performance | Synthetic polymer (plastic-rubber blend) | Cushions impacts, resists compaction, retains shape long-term | Higher cost than SBR |

| Cork | Performance | Organic (cork granules) | Absorbs shock, reduces surface heat, eco-friendly, no smell | Can degrade over time, require more maintenance |

| BrockFILL | Performance | Organic (engineered pine particles) | Improves traction, minimizes splash, cooler, natural | Limited availability compared to synthetic options, higher cost |

The world of infill for artificial turf offers a diverse range of options, each designed to meet specific needs and preferences. What is the best infill for artificial grass? The answer depends on your priorities.

While all infill types can be used to build high-performance synthetic turf fields, the best choice often comes down to factors like sustainability goals, surface temperature, maintenance requirements, and budget.

Comparing SBR and Cork in a Tested Turf System

SBR and cork are widely seen as benchmarks for traditional and natural infills, respectively. After looking at the range of available infill types and their general characteristics, it’s helpful to take a closer look at how two of the most representative options actually perform on the field. By comparing their performance in the same turf system, we gain a clearer understanding of the practical trade-offs involved.

The test system was CCGrass Pride UP, a premium turf featuring a ribbed diamond-shaped yarn made from advanced polymer. This system has been tested to both FIFA Quality and FIFA Quality Pro standards with SBR and cork infills.

| CCGrass Pride UP 40 | With SBR | With Cork | FIFA Standard |

| Rotational Resistance | 37Nm | 38Nm | 20–50Nm |

| Vertical Ball Rebound | 0.80m | 0.83m | 0.6–1.0m |

| Angle Ball Rebound | 52% | 55% | 45-70% |

| Reduced Ball Roll – new | 6.8m | 6.3m | 4-10m |

| Reduced Ball Roll – 6000 cycles | 8.7m | 7.8m | 4–12m |

| Shock Absorption | 64% | 63% | 60-75% |

| Deformation | 9mm | 8mm | ≤16mm |

| Surface Friction | 0.7 | 0.7 | 0.35–0.75 |

Similar overall performance: The results show that both SBR and cork provide excellent performance, comfortably within FIFA’s required range across all metrics.

Ball Roll performance:Cork offers a shorter ball roll (6.3m new, 7.8m worn) than SBR (6.8m new, 8.7m worn), improving control in both conditions. It also offers better consistency, changing less over time (1.5m vs. 1.9m). This may be due to cork’s lightweight and elastic nature.

Practical differences: SBR is widely available and cost-effective. Cork offers sustainability and a cooler surface, but may require more frequent top-ups and costs about £1.5 or €1.75 more per square meter.

Overall, both SBR and cork infills support high-level play, with the choice depending on budget, sustainability priorities, and maintenance needs.

What’s the Difference between Infill and Non-infill Turf?

The main difference lies in how turf systems achieve performance. Traditional synthetic turf includes loose performance infill as part of the system, while non-infill turf, a growing alternative, is designed to work without it.

Instead, it relies on a dense thatch layer of strong, curly fibers to fulfill similar functions. This layer supports the straight pile yarns by locking them firmly in place, while contributing to grip, shock absorption, energy return, and proper ball bounce.

Cleaner play experience: Non-infill systems prevent infill splash and microplastic spread, ensuring a cleaner, eco-friendly surface.

Cost-effective: With no infill to transport, install, or maintain, these fields reduce logistics, installation operations, brushing, topping up, and decompaction, lowering labor costs over time.

Easier end-of-life recycling: Without infill, dismantling and recycling at the turf’s end-of-life are simpler, enhancing sustainability.

For projects prioritizing minimal maintenance, environmental stewardship, and clean aesthetics, non-infill synthetic turf offers a smart alternative. Our proven, high-performing non-infill products meet these needs, ensuring durability and sustainability without compromising quality.

Conclusion

Artificial grass infill plays a crucial role in delivering the performance, safety, and longevity expected from modern synthetic turf systems. Whether you prefer traditional rubber, natural infills, or explore non-infill systems, understanding the available options allows you to choose what best fits your project’s goals and priorities.

Featuring “Preferred” status in the three major global field sports—football, hockey, and rugby—we offer a wide range of proven turf systems for all levels of play.

Backed by extensive experience and expertise, we guide our clients through every step—from selecting turf and infill to system design, installation, and ongoing maintenance—ensuring an optimal solution tailored to their specific needs.