Discover Leap Turf System

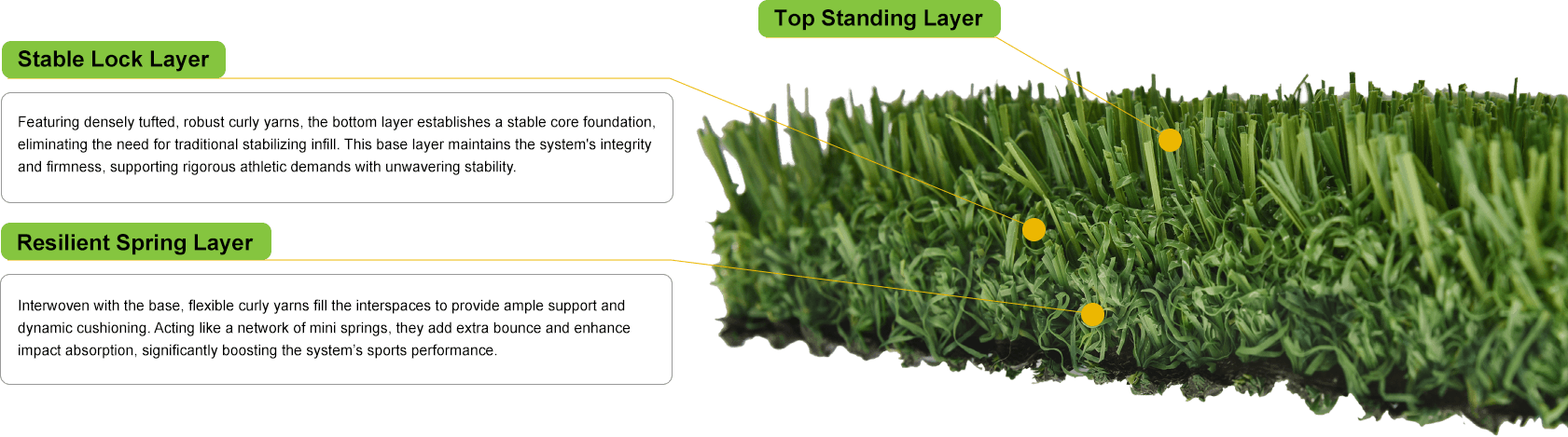

Stable Lock Layer

Featuring densely tufted, robust curly yarns, the bottom layer establishes a stable core foundation, eliminating the need for traditional stabilizing infill. This base layer maintains the system's integrity and firmness, supporting rigorous athletic demands with unwavering stability.

Resilient Spring Layer

Interwoven with the base, flexible curly yarns fill the interspaces to provide ample support and dynamic cushioning. Acting like a network of mini springs, they add extra bounce and enhance impact absorption, significantly boosting the system’s sports performance.

Top Standing Layer

Reliable and Proven Sports Performance

Shock Absorption

>60%

Shock Absorption

4-11MM

Ball Rebound

0.6-1.0M

Ball Roll

4-10M

Withdrawal Force

≥40 N

UVA

5000 H

Resilient Support

A multi-dimensional fiber design creates an ultra-dense, resilient playing surface, enhancing overall game quality. The strong, curly yarns provide stable and firm support by tightly winding and locking the straight yarns. This improves the standability of grass, enabling it to recover quickly after compression.

Shock Absorption

Leap’s high-density surface acts as a cushion that absorbs and dissipates the energy generated when athletes run, jump and fall. Enhanced shock absorption translates to better protection for athletes, reducing the risk of injuries from impacts.

Superior Sports Experience

Leap is engineered with optimal friction levels to ensure the boll rolls smoothly without unexpected deviations in speed or direction.

Proper rotational resistance enhances player agility and performance, enabling swift and safe directional changes without the risk of losing balance. It’s crucial for preventing slips and falls in high-speed sports.

Reliable Durability

The straight yarn, made from high-grade polymer with a diamond shape, is one of the most popular and durable yarns on the market. Tested beyond 30,000 Lisport cycles and 5,000 hours of UVA exposure, it delivers exceptional wear resistance and long-lasting performance under intensive use.

LEAP TURF SYSTEM

– AN ECO-FRIENDLY SOLUTION

Featuring a unique high-density structure, Leap eliminates the need for traditional infills, such as crumb rubber or plastic granules, effectively avoiding infill loss issues.

With traditional turfs, separating infill from the yarns is a complex, often economically unfeasible process, leading to lower recycling rates and higher disposal in landfills. In contrast, Leap consists solely of grass fibers and backing, significantly simplifying the recycling process. This streamlined composition not only enhances the quality of the final recycled material but also reduces processing costs, making the entire product more easily recyclable.

By opting for Leap, we’re selecting a greener, cleaner playing surface that doesn’t compromise on performance while actively contributing to environmental sustainability.

Leap Turf System – A Cost-Effective Option

Saving Installation Cost

The installation of Leap is quicker and less labor-intensive since it does not require the additional steps of infill delivery, spreading, and settling. This streamlined process will reduce initial setup costs and significantly improve installation efficiency.

Cutting Shock Pad Cost

Conventional turf systems generally require thicker shock pads to achieve adequate shock absorption. In contrast, the Leap system can achieve similar or superior performance with regular shock pads due to its unique high-density structure.

Low Maintenance Cost

The real non-infill system offers substantial cost savings over time by minimizing the need for routine maintenance, such as replenishing infill, decompaction, and cleaning the particles lost from the playing fields. These maintenance tasks require time, labor, and equipment, which all add up to long-term upkeep costs.

No Extra Infills Cost

Since no infill is required, the ongoing costs associated with purchasing and replenishing infill materials are eliminated. This results in considerable long-term savings compared to traditional systems that rely on regular infill top-ups.

Leap Field Highlights

Get a Free Sample

Want to learn more about Leap? Reach out to get our Leap brochure or request a free sample—our team is here to help.